#ECOStep >

Asking challenging questions of ourselves and our suppliers. Focusing on the environment. Finding innovative solutions for model development to optimise work processes. Encouraging the use of future-oriented materials. This is how we develop our technologies and products day by day – for a future worth living.

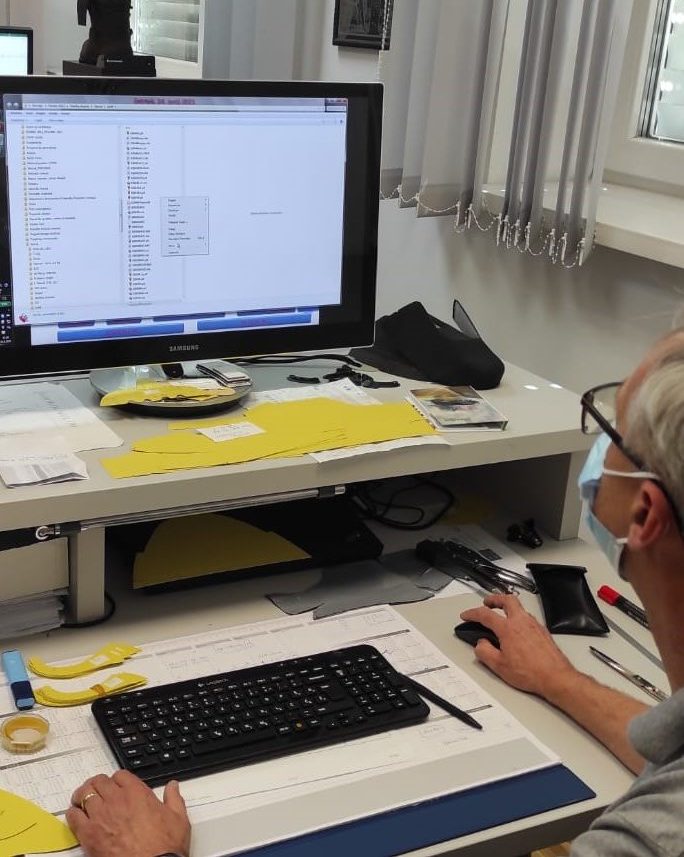

- All models are completely developed in-house, from the last to the sole, and prepared for production.

- Through various projects, the course is set in development for more sustainable products and processes. Here is an overview:

- Increasing the recycled content of components, without loss of quality and reduction of longevity.

- How can solvent content in adhesives be reduced? For example, the pre-stitching step has already been optimised, with the result that we have been able to reduce the need for solvents by 45%.

- Elimination of harmful PFCs in the production process.

- Development of cut-optimising processes to reduce production waste.

Reduction of solvents in production: Here during the “painting” of the rubber belt.

The development of the shoes takes place in our own hands.

Since the first boot, we at Meindl have been committed to honest cooperation, down-to-earthness and living tradition. For our family, sustainability has always been a matter of course and this will remain so!

Lukas and Lars Meindl